SARCON® “CASE” SHAPE MOLDED

THERMAL INTERFACE MATERIALS

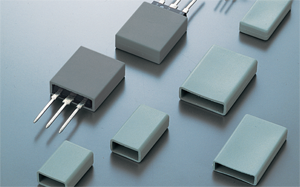

Box-shaped caps for transistors. High thermal dissipation rate. Open on one end; installs by just slipping over the desired components. Available in TR and HR materials. All standard items in stock; custom sizes available.

APPLICATIONS:

Semiconductor packages, thermistors

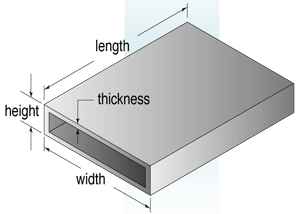

| Inside Dimensions | Case Thickness |

||||

|---|---|---|---|---|---|

| Part Number | Type | Length | Width | Height | |

| 30T-TO-220-02225 | TR | 22.5 | 11.0 | 4.5 | 0.30 |

| 45T-TO-220-01220 | TR | 22.0 | 11.0 | 5.0 | 0.45 |

| 90T-TO-220-01220 | TR | 22.0 | 11.0 | 5.0 | 0.90 |

| 30T-TO-3P-03281 | TR | 28.1 | 16.0 | 4.5 | 0.30 |

| 50T-TO-3P-02275 | TR | 27.5 | 16.5 | 5.0 | 0.50 |

| 90T-TO-3P-01280 | TR | 28.0 | 18.0 | 5.0 | 0.90 |

| 45H-TO-220-01220 | HR | 22.0 | 11.0 | 5.0 | 0.45 |

| 90H-TO-220-01220 | HR | 22.0 | 11.0 | 5.0 | 0.90 |

| 50H-TO-3P-02275 | HR | 27.5 | 16.5 | 5.0 | 0.50 |

| 90H-TO-3P-01280 | HR | 28.0 | 18.0 | 5.0 | 0.90 |

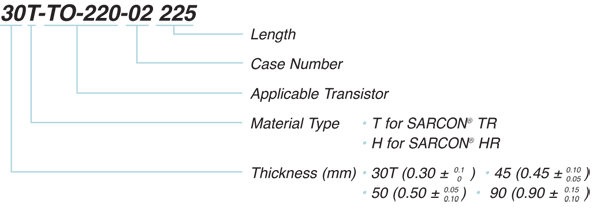

PART NUMBER NOMENCLATURE: