SARCON® Thermal Gap Filler Products

SARCON® Thermal Gap Filler Pads are highly conformable and high heat conducting gel materials in a versatile sheet form. They easily fit and adhere to most all shapes and sizes of components, including protrusions and recessed areas.

In areas where space between surfaces is uneven or varies and where surface textures are a concern regarding efficient thermal transfer, the supple consistency of the pads is excellent for filling air gaps and uneven surfaces. Four series, each with a different construction, accommodate most every demanding application.

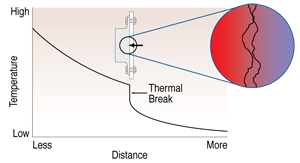

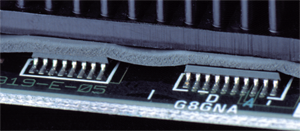

Thermal impedance of semiconductor mounted to substrate is appreciably increased at junction of porous surfaces.

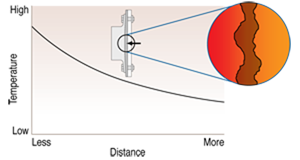

Thermal impedance of semiconductor mounted to substrate with gap filler pad is eliminated yielding higher temperature gradient.

As shown above, even the most highly polished mating surfaces do not make reliable contact surfaces. Complete physical contact is necessary to minimize the resistance to heat flow for the best thermally conductive path. All such surface voids, when properly filled with a conformable, thermally conductive GR series gap filler pad, will in most cases exhibit the continuous characteristics of a solid metal of the same dimensions.

UL FILE NUMBER: E58126

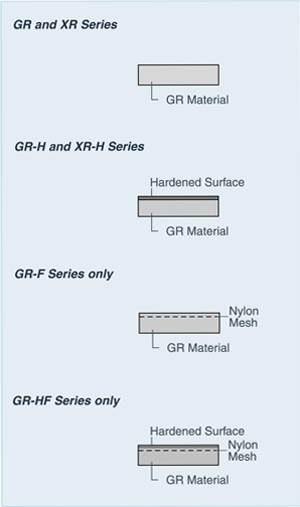

Construction

The basic GR Gap Filler Pad series can be further enhanced for special handling and die-cutting requirements as described following in the chart at the lower left. Gap filler materials are supplied in a fully cured state and remain pliable, easily conforming to minute surface irregularities.

| Construction Description | “GR-ae” | “GR25A” | “GR14A” |

|---|---|---|---|

| General purpose silicone compound | GR-ae (G-ae) UL94 V-0 |

GR25A-00 UL94 V-0 |

GR14A-00 UL94 V-0 |

| • Between chassis wall and other surface • Between semi conductor and heat sink • Large area heat transfer to heat sink • Between CPU and heat sink |

|||

| Same general purpose silicone compound as above plus additional hardening of the top surface to facilitate handling and installation during complex assemblies. | GR-Hae (G-Hae) |

GR25A-0H | GR14A-0H |

| Same as above, except hardened top surface allows handling without distortion in cases where this feature is required. | |||

| Same general purpose silicone compound as above plus mesh reinforcement stiffener to prevent stretching; i.e, elongation of die-cut holes. | GR-Fae (G-Fae) |

GR25A-F0 | N/A |

| Same as GR basic formula, plus specific construction for intricate die-cut shapes to prevent distortion of the die-cut shape during die-cutting and installation. | |||

| Same general purpose silicone compound as above plus additional hardening of the top surface to facilitate handling and installation during complex assemblies, and mesh reinforcement stiffener to prevent stretching; i.e., elongation of die-cut holes. | GR-HFae (G-HFae) |

GR25A-FH | N/A |

| Same as GR basic formula, plus specific construction with hardened top surface and mesh reinforcement for die-cutting and handling without distortion. | |||

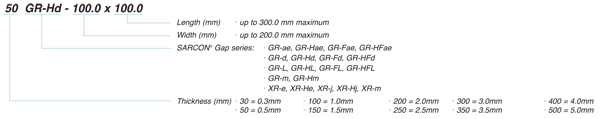

PART NUMBER NOMENCLATURE:

Standard: To specify a part number to your exact specifications, substitute the metric measurements for thickness, width an length according to the instructions below; example part# 50 GR-Hd-100.0-100.0